Max Sheet Size 48"x 96" - $11,500.00 plus shipping

CLS-408 - 4' x 8' System

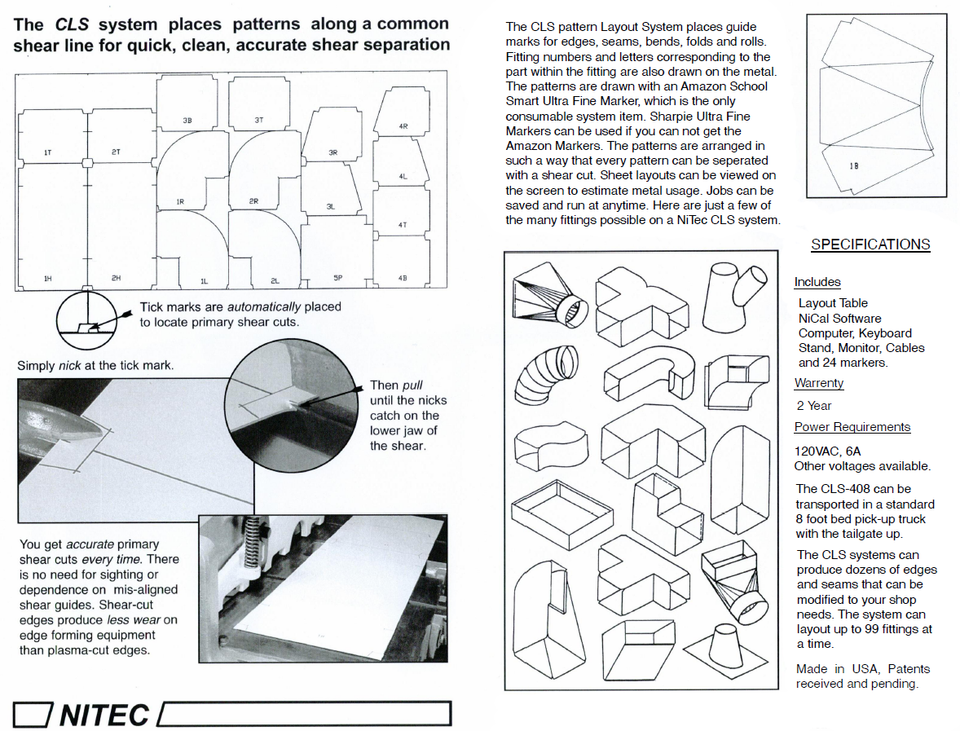

COMPLETE SYSTEM INCLUDES:

- Layout Table, Software, Computer

- Monitor, Stand, Cables and Pens

- 2 Year Warranty

Layout systems create and draw patterns for sheet metal duct and fittings used in HVAC, Dust Collection and Roofing.

An inexpensive alternative to plasma systems.